20 October 2025

The wonderful world of foil: different printing techniques highlighted

Updated: 23 October 2025

Foil plays a special role in the world of packaging. It adds luxury, shine and a unique look, which makes all the difference, especially in chocolate packaging. However, foil is not a single technique, but a collective term for various printing and finishing techniques, each with its own characteristics and applications.

In this article, we explore the most important foil techniques: what they entail, what print runs they are suitable for, and how they contribute to the premium look of your chocolate products. We base our information on data from the Foil & Specialty Effects Association (FSEA) and link this to Lareka's practical experience.

What is foil and why is it so popular?

Foil is a thin layer of metallic or coloured film that is applied to paper or cardboard. Its reflective properties immediately give packaging a premium look. In addition, foil can be combined with techniques such as embossing for extra tactile effects.

Foil is popular for chocolate wrappers and packaging because it visually enhances the exclusivity and quality of the product, while also being practical in production processes.

Hot foil stamping

Hot foil stamping uses a heated metal stamp to press the foil directly onto the paper. This process creates a subtle impression in the paper and makes it possible to apply foil and embossing in a single step. This technique is particularly suitable for medium to large print runs, due to the stamps required and production time.

Cold foil transfer

Cold foil transfer takes place inline on flexographic or offset printing presses. First, an adhesive layer is applied, after which the foil sticks to the right places. Immediately afterwards, ink can be printed over the foil in the same printing run, which allows for a wide range of metallic colours. This is ideal for larger print runs and extensive foil areas.

An example of hot foil stamping from our customer Chocolaterie L' Amy

Digital foil techniques: toner-based and polymer-based

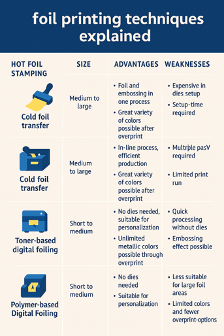

Digital foiling makes it possible to apply foil without dies, which is particularly interesting for short to medium runs and personalised packaging. There are two main types:

- Toner-based digital foiling: A black toner layer is printed onto which the foil is applied using heat. CMYK can then be printed over the foil, creating many different metallic colours. This process requires multiple passes and offers a great deal of flexibility

- Polymer-based digital foiling: A transparent polymer adhesive layer is applied, followed by the foil. A thicker layer of adhesive creates a slight embossing, which provides a tactile experience. This technique is fast and suitable for shorter print runs, but offers fewer colour variations.

When is which technique most beneficial?

The choice of foil technique depends mainly on the print run, the design and the desired effect. Hot foil stamping and cold foil transfer are cost-effective for medium to large print runs, especially when a lot of foil is used. Digital foil methods are more attractive for smaller print runs and offer the possibility of personalisation.

Below is a summary table with the most important characteristics depending on the production size and printing technique:

Lareka and foil: innovation in chocolate packaging

At Lareka, we support chocolatiers with advanced packaging machines that closely match the needs of our markets. Our machines, such as the BTB25 and NP60, help to process packaging quickly, accurately and with an eye for quality.

We are seeing foil techniques being used more and more to make chocolate packaging extra exclusive. The combination of innovative foil methods and our reliable machines makes it possible to efficiently produce both large series and exclusive small runs.

Whether it's traditional hot foil stamping, cold foil transfer, or modern digital foil methods, Lareka helps chocolatiers to distinguish and surprise with their packaging.

Do you still have questions about foil or other chocolate packaging-related topics after reading this article? Get in touch with us, we're happy to help!